BS 1362 Fuse Operation Characteristics

A common misunderstanding is that a 13A fuse is designed to blow at 13A. This is not the case. Under BS 1362, the rated current of a fuse is the current it can carry continuously without exceeding its permitted temperature rise. In practice, a 13A fuse can carry approximately 20A for a significant period without operating.

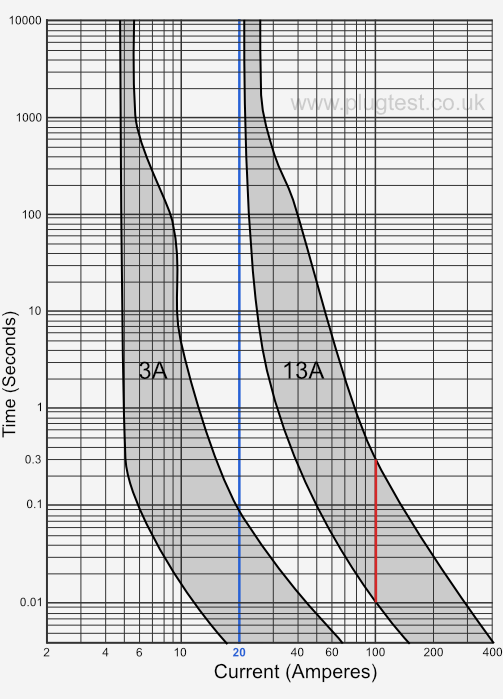

Figure 1 shows the time-current characteristics for 3A and 13A BS 1362 fuses. The shaded region indicates the zone within which the fuse is required to operate. For example, at a fault current of 100A (shown in red), a 13A fuse will operate within 0.01–0.3 seconds. However, at 20A (shown in blue), the fuse will not operate.

Why does a 13A rated fuse not blow at 13A?

The wire inside a fuse heats up when a current passes through it. The more current that passes, the hotter the wire will get. If the current is high enough, the wire will melt and cut the power to the appliance. The rated current of the fuse, in this case 13A, is the current that it can safely pass while keeping the fuse/plug temperature within safe limits. BS 1362, the British Standard for fuses used in 13A plugs, specifies that at the rated current the fuse must not dissipate more than 1 watt (1W). This limits the temperature rise within the plug under normal operating conditions.

Non-Fusing Current

The non-fusing current, the current that the fuse is capable of carrying, is specified as 1.6 times the rated current (Inf = 1.6 In). The fuse must be capable of carrying the non-fusing current for at least 30 minutes. So a 13A fuse must be capable of maintaining a current of 20.8A for at least 30 minutes without blowing.

Fusing Current

BS 1362 also specifies the fusing current as 1.9 times the rated current (If = 1.9 In). If the current exceeds the fusing current, the fuse must blow within 30 minutes. So a 13A fuse must blow within 30 minutes when carrying a current that exceeds 24.7A.

Overloading and Overheating

Figure 2 shows an example of an overheated plug fitted to an extension lead. This is likely to be caused by a combination of overloading of the extension lead and a loose terminal connection. The fuse has sustained a current above its rated value, but below the point where it will operate and break the circuit. In this case, the pin has heated up sufficiently to damage both the plug and socket. This highlights why the cardboard wiring instruction card supplied inside new plugs should always be removed before use. If a plug overheats due to overload or a loose connection, the presence of combustible material inside the plug only increases the fire risk. Fortunately, the British Standard for the 13A plug requires the use of fire-retardant plastic, preventing such incidents from turning into fires. Nevertheless, there is a growing number of counterfeit plugs made from flammable plastic sold online. We have published an article about counterfeit plugs, in which we conduct a flammability test to illustrate the potential hazards. Incorporating the identification of substandard and fake electrical equipment into the PAT testing inspection process is becoming increasingly crucial, and it is an essential aspect that we address in our PAT testing courses.