Managing PAT Testing in the Workplace

This guide is for duty holders and managers responsible for electrical safety. Whether PAT testing is outsourced or done in-house, you’re responsible for having a sensible system in place: deciding what is included, setting risk-based frequencies, making sure defects are reported, and keeping enough records to show due diligence.

- Legal responsibilities and what “PAT” actually means

- What to include in your equipment register

- Setting frequencies using risk assessment

- Records, labelling and defect management

- User checks, training and workplace policies

- Outsourcing vs in-house testing

Legal Responsibilities

The Electricity at Work Regulations 1989 require electrical systems and equipment to be maintained so far as is reasonably practicable to prevent danger. In practice, this means you need a proportionate system for identifying hazards, managing risks and acting on defects. Portable Appliance Testing (PAT) is one recognised way of doing this because it combines visual inspection with appropriate electrical tests as part of a planned maintenance routine. For more detail, see our article on the legal requirements of PAT testing.

What is Portable Appliance Testing (PAT)?

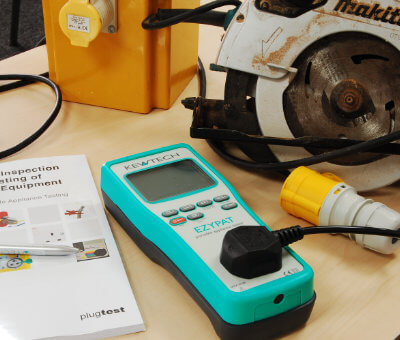

PAT testing is a practical way of managing the safety of electrical equipment. It typically includes a user check (simple visual checks), a formal visual inspection (including plug wiring and cable grip where applicable), and electrical testing. The IET Code of Practice provides guidance on how inspection and testing should be carried out and recorded.

What Equipment Needs to be Tested?

Despite the name, PAT is not limited to “portable appliances”. In a workplace, your system should cover electrical equipment that is connected (or could be connected) to the supply — including items plugged into sockets and equipment permanently connected via a fused spur. The most practical approach is to maintain an equipment register and assess items by type, environment and use. See our guide to types of electrical equipment.

How often should it be Done?

There are no fixed legal intervals for PAT testing. Frequencies should be set using a risk assessment based on the equipment type, how and where it is used, who uses it, and what you’ve found previously. High-risk items (for example, hand-held tools in workshops) need more frequent checks than low-risk items (such as office IT equipment). Our guide to risk assessment for PAT testing frequency explains how to set sensible intervals and when additional control measures are needed.

Maintaining Test Records

Keeping records is not always a legal requirement, but it is an excellent management tool and helps demonstrate due diligence. Records help you track recurring damage, identify problem areas, review frequencies, and prove defects were acted on.

At a minimum, records should include: equipment description, a unique ID (asset number or serial number), location, inspection and test results, date, and the person/company carrying out the work. Where equipment fails, record the action taken (removed from service, repaired, retested, disposed of).

Labelling

Labelling makes it obvious that an item has been inspected and helps link it to your records (for example using an asset number). Choose labels that will survive until the next inspection. For tools and equipment in harsh environments, extra protection may be needed, for example a Snaptag label holder.

User Checks and Staff Training

User checks are one of the most effective controls because many faults are visible before a test is due. Staff should know what to look for (damaged plugs, crushed cables, signs of overheating) and how to report defects so equipment can be removed from service quickly. See our guide to user checks.

New Equipment

New equipment does not normally need electrical testing before first use, but it should be visually checked for transit damage and obvious defects. Add it to your equipment register and set an initial inspection/test frequency based on risk.

A simple purchasing policy also helps reduce risk. Buying from reputable suppliers reduces the likelihood of counterfeit or substandard electrical products entering the workplace, particularly for high-risk items such as heaters, chargers and extension leads.

Personal Electrical Equipment Policy

Personal electrical items (chargers, heaters, desk fans, extension leads) can undermine an otherwise good system because origin, condition and suitability are unknown. Consider a clear policy: either restrict personal items, or require inspection/testing before use, plus a system for reporting defects.

Damaged or Faulty Equipment

When equipment is found to be damaged or faulty during inspection or testing, it must be dealt with immediately. A clear and consistent procedure helps prevent unsafe items from remaining in service and demonstrates effective management.

If an item fails inspection or testing, the following steps should be taken:

- Remove from service immediately – The equipment must not continue to be used.

- Clearly label the item – Attach a “Failed” or “Do Not Use” label to prevent accidental reuse.

- Report to the responsible person – Ensure the duty holder or nominated manager is informed.

- Assess the cause of failure – Consider whether the damage is accidental or whether it indicates that the equipment is unsuitable for its intended use or environment.

- Repair, replace or substitute – Repairs must only be carried out by a competent person. Where equipment repeatedly fails due to damage, it may need to be replaced with a more robust type designed for the environment. In some cases, a safer alternative — such as battery-powered equipment instead of 230V mains-operated tools — may be appropriate to reduce or eliminate the risk.

- Retest before return to service – Any repaired equipment should be formally inspected and tested before being put back into use.

- Update records – Record what was found and what action was taken.

Repeated failures should never simply be treated as a maintenance issue. They often indicate a wider management problem, such as unsuitable equipment selection, harsh environmental conditions, or inadequate user training. Addressing the root cause is an important part of effective risk control. A simple, clearly communicated failure procedure is one of the most important parts of an effective PAT management system.

Outsourcing PAT Testing

Outsourcing can be efficient, but you still need to define what “good” looks like. Agree scope (what is included/excluded), site access arrangements, how failures are handled, the format of records, and how items are labelled. Make sure the contractor understands your locations, environments and any site-specific rules.

In-House PAT Testing

In-house inspection and testing can reduce disruption and improve control, especially where equipment moves between areas or is used outside normal hours. Whoever carries out the work must be competent and trained, with knowledge to select the correct tests and interpret results. If you’re unsure whether in-house PAT testing is appropriate for your organisation, see our Can I do my own PAT testing? article. If you decide to train staff for this role, see our PAT Competent Person course.

Conclusion

Whether you choose to outsource your PAT testing or handle it in-house, as a duty holder you have the overall responsibility for overseeing the safety of the electrical equipment within the workplace. It involves not only conducting the necessary tests but also establishing a system of maintenance, but it does not need to be overly complicated, it is all about taking sensible and proportionate measures to control the risks in the workplace.

Further reading

- The IET Code of Practice For In-Service Inspection and Testing of Electrical Equipment* provides information on both the management of PAT testing and also the practical details of how to perform the inspection and tests. *Amazon affiliate link - we may earn a small commission.

- HSE - Maintaining Portable Electrical Equipment outlines a recommended maintenance plan for a system of user checks, and visual inspection and testing.

- HSE - Maintaining Portable Electrical Equipment in Low-Risk Environments. This document provides simple and practical advice on managing electrical equipment in low-risk environments such as offices and shops.