Identifying counterfeit and substandard chargers

Counterfeit and substandard mobile phone chargers (and other AC adaptors) are widely sold online, particularly via marketplaces such as eBay. This matters during PAT testing because a charger can look fine externally yet have serious safety defects internally. The good news is that many unsafe chargers can be screened out during the visual inspection using a few simple checks.

If you’d like an overview of other real examples we’ve found during inspection and PAT testing, see our page on counterfeit and dangerous electrical equipment.

Key takeaways

Visual inspection is critical. Many counterfeit and substandard chargers can be identified before testing by checking pin dimensions, spacing, markings and overall build quality.

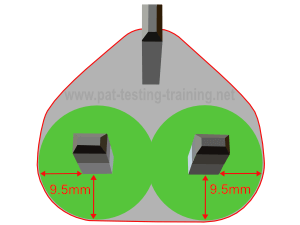

Pin spacing and edge clearance matter. There must be at least 9.5 mm between the Line and Neutral pins and the outer edge of the device.

Check the CE mark carefully. Incorrect proportions, missing spacing between letters, or markings that are too small are common indicators of counterfeit products.

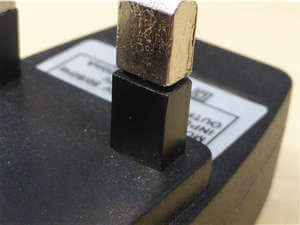

Low quality construction is a warning sign. Loose, undersized or poorly plated pins, moulding defects and lightweight construction often indicate non-compliance.

Electrical tests alone are not enough. Some dangerous chargers may pass basic electrical tests yet still present a shock or fire risk due to poor internal isolation.

Pin spacing to the outer edge

For UK plug-in equipment, there must be sufficient clearance between live pins and the outer surface of the adaptor. During inspection, look for at least 9.5 mm between the Line/Neutral pins and the outer edge of the case. Many counterfeit chargers fail this basic requirement.

Incorrect CE Mark

Check the CE mark carefully. On counterfeit products it’s often printed at the wrong size, in the wrong proportions, or with incorrect spacing. A poor CE mark on its own doesn’t prove a charger is unsafe, but it’s a strong warning sign that the product may be non-compliant.

- Should have a minimum height of 5mm

- Should be in correct proportions

- Should be a noticeable space between 'C' & 'E'

- The thickness of the lines will be in proportion to the overall size

- The centre line of the 'E' should be noticeable shorter than the top & bottom lines

For further information, check out our article on CE Marks.

Low Quality Construction

This example was purchased on eBay for 99p (including delivery). The Line and Neutral pins are loose and undersized, with burrs and poor plating. Pin dimensions and alignment are critical to ensure a safe connection and should comply with BS 1363. These can be verified using a plug pin gauge as part of a formal visual inspection. Even before electrical testing, the overall build quality of this charger indicates it is unlikely to meet the mechanical or electrical safety requirements expected of compliant equipment.

What to do if you find a suspect charger

If a charger looks suspicious, treat it as a failed visual inspection.

- Remove it from service.

- Replace with a reputable brand (or an OEM charger supplied with the device), purchased from a trusted electrical distributor/retailer.

- Record it as a failed visual inspection and note the reason (e.g. poor pin spacing, loose pins, suspect markings, damage).

- Don’t rely on electrical tests alone. Many dangerous faults relate to internal construction, insulation distances and isolation barriers that aren’t obvious from basic electrical tests.

Fire Risk

Substandard chargers can present a serious fire risk due to poor internal construction, inadequate insulation, or overheating components. Many counterfeit chargers lack the internal protective features required by safety standards, including proper isolation between the mains input and low-voltage output. This means a fault inside the charger can result in overheating, electric shock risk, or fire. These defects are often not detectable by electrical tests alone, which is why careful visual inspection forms an essential part of PAT testing. Chargers with poor pin dimensions, incorrect markings, or low-quality construction should be removed from service immediately. Fire and rescue services regularly attend incidents caused by faulty or counterfeit chargers, highlighting the importance of identifying unsafe equipment before it fails in use.

View tweet on X

View tweet on X

Conclusion

Counterfeit chargers often fail basic mechanical and marking checks and may also have dangerous internal construction. The most effective control is a thorough formal visual inspection, backed up by purchasing policy: use reputable suppliers and avoid unusually cheap, unbranded marketplace listings.

For more real-world examples found during inspection and PAT testing, see our hub page on counterfeit and dangerous electrical equipment.

If you’d like hands-on training that covers visual inspection in depth (including examples like these), see our PAT testing courses.

Frequently asked questions

Can PAT testing detect a counterfeit charger?

Not reliably on its own. Some problems are obvious during electrical tests, but many of the most serious issues relate to internal construction and insulation distances. That’s why the formal visual inspection is so important.

What are the most common warning signs?

Loose or undersized pins, poor clearance around live pins, crude moulding, incorrect or suspicious markings, and very low purchase price from an unknown seller.

What should I do if I find one in the workplace?

Remove it from service, record it as a failed visual inspection, and replace it with a charger from a reputable brand and supplier.

Are all cheap chargers unsafe?

No, but unusually cheap chargers sold through marketplaces are higher risk. A good purchasing policy and consistent inspection are the best controls.