Class I and Class II Equipment Explained

When it comes to electrical safety, we often encounter terms such as basic protection, fault protection, and various classes of equipment like Class I and Class II. In this article, we'll break down these terms, explore how different classes of equipment safeguard users from electric shocks, and provide typical examples of items falling under each class.

Basic Protection and Fault Protection

Fundamental to the design of safe electrical products is the principle of basic protection and fault protection.

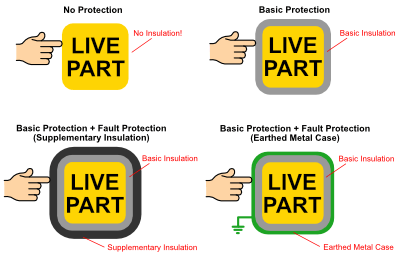

Basic Protection is the first layer of safety in an electrical appliance. It prevents direct contact with electrical current under normal operating conditions. The most obvious form of basic protection is a non-conductive material such as plastic or rubber covering live electrical components. However, as air is also an excellent electrical insulator, basic protection can be provided by a simple air gap coupled with a physical barrier, such as the casing of the equipment, to prevent accidental contact with live parts.

Fault Protection can be thought of as an additional safety measure in case the basic protection fails. This can either be provided by earthing in Class I equipment or by additional insulation in Class II equipment.

Class I Equipment

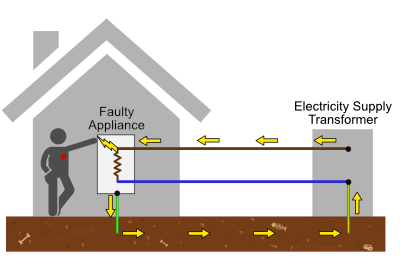

In a Class I appliance, the body or casing, which is usually made of metal, is connected to earth via an earth wire and plug. This earth connection provides an alternate path for electric current to flow in case of a fault, such as a failure of basic insulation.

The earth circuit is designed to have low resistance. Why is this important? It's because, in the event of a fault, this low-resistance path ensures that a high current will flow. This high current, in turn, triggers the circuit protection device in the electrical installation, such as a fuse or circuit breaker. The protection device is designed to detect this surge of current and respond by cutting off the power to the appliance.

By swiftly cutting off the power, the circuit protection device prevents the appliance casing from remaining live and posing a risk of electric shock to anyone who touches it. An important part of the PAT testing process is measuring the resistance of the earth circuit within the appliance to ensure it has a low enough resistance to trigger the circuit protection device in the event of a fault.

Examples of Class I equipment typically include larger appliances like refrigerators, washing machines, that usually have metal cases, and also some smaller appliances such as kettles and irons.

Class II Equipment

Fault protection in Class II equipment is achieved by an additional layer of insulation. This supplementary insulation layer protects the user from coming in contact with live parts should the basic insulation fail. For this reason, Class II appliances are often known as "double insulated". However, a single layer of reinforced insulation can also be used. The reinforced insulation provides an equivalent level of protection as the basic and supplementary insulation layers combined.

A significant advantage of Class II construction is that it does not rely on the earthing provided by the building's wiring for protection. Even if the earthing in the building's wiring is faulty or non-existent, Class II equipment still provides reliable protection against electric shock.

During a PAT test, an insulation resistance test is typically carried out at a high voltage, usually 500V. This test is essentially a 'pressure test' for the insulation, measuring its resistance to ensure it is high enough to protect the user even under strenuous conditions.

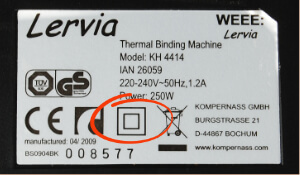

Class II equipment typically includes smaller appliances like electric drills, hairdryers, and table lamps. Class II appliances can be identified by a square within a square symbol ⧈. This symbol is usually on the label with the power and voltage rating. Alternatively, it is sometimes embossed directly on the plastic case.

Conclusion

Understanding the difference between Class I and Class II equipment is not just a matter of theory. This knowledge is crucial for anyone involved in PAT (Portable Appliance Testing) and for those who wish to ensure the safety of electrical appliances in their workplaces or homes. By knowing how each class of equipment is designed to protect users from electric shocks, we can better appreciate the importance of the safety measures embedded in these devices.

If you'd like to learn more about PAT testing and electrical safety or if you are interested in our training courses, feel free to get in touch.