Leakage Current Test

The leakage test can be used as an alternative to the insulation test. It’s a useful test to perform where an appliance has an electronic switch that requires mains power to operate, or for equipment containing surge protection circuits which often give low insulation resistance readings.

Most modern PAT instruments carry out a leakage test as part of their auto test sequences, however it’s not a test required by the IET Code of Practice, rather it is intended to be used as an alternative, or in addition to the insulation test.

For Class I equipment, the leakage test measures the current flowing through the protective conductor (earth wire) whilst powered at the supply voltage. A leakage test on Class I equipment is therefore referred to as a Protective Conductor Current Test. In practice, most test instruments measure the difference between the current flowing through the line and neutral conductors. Any difference can be considered as leaking through the protective conductor. Therefore is is often described by test instrument manufacturers as a Differential Leakage Test.

For Class II equipment, the leakage test is made by attaching the test lead to any exposed metal parts of the equipment and measuring the current flowing through the test lead. The test instrument uses a 2kΩ resistor to represent the current that would typically flow through the human body. The leakage test on Class II equipment is referred to as a Touch Current Test.

Many test instruments also have a substitute or alternative leakage test. The substitute leakage test applies a reduced ac voltage, typically 40 - 60 Vac, between the line and neutral joined together and the earth conductor, or test lead for Class II equipment. The instruments then calculates the leakage current that would be expected if the appliance was operating at the supply voltage. The substitute leakage test was initially used for testing computers to prevent them from powering up for just a few seconds which could cause errors when rebooting. More recently, with the introduction of battery-operated test instruments, the substitute leakage test is often included in the standard test sequences for Class I and Class II equipment. Because the substitute leakage test does not measure the actual leakage current at mains voltage, it can be inaccurate and therefore can not be used as an alternative to the insulation test. Some battery-operated models can be connected to the mains supply to carry out a true leakage test at mains voltage.

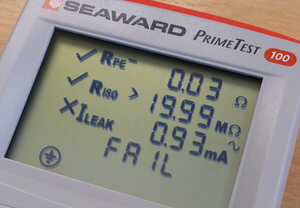

Leakage Test Fail

The most common reason why equipment often appears to fail a leakage test is that an incorrect limit is used. The limit for the leakage test was changed in the 5th edition of the IET Code of Practice to 5mA for all Class I and Class II equipment. Most test instruments are preset to the older leakage limits based on previous editions of the IET Code of Practice. If the test instrument can not be reprogrammed with the 5mA limit, some manual interpretation of the test result will be required to prevent unnecessarily failing equipment. A leakage measurement of 5mA or less should be considered a pass.

| Appliance Type | Old Limit | 5th Edition Limit |

|---|---|---|

| Class I Handheld & Portable | 0.75mA | 5mA |

| Class I IT, Movable, Stationary & Fixed | 3.5mA | 5mA |

| Class I Heating & Cooking | 0.75 mA or 0.75 mA per kW, whichever is greater, with a maximum of 5 mA |

5mA |

| Class II All Types | 0.25mA | 5mA |

Some equipment is designed to operate with a leakage higher than the 5mA limit. Because there is a risk of an electric shock if the protective conductor becomes disconnected, extra precautions are required. They must be permanently wired to the fixed installation or connected with an industrial plug and socket. They should also have a label warning of the high leakage current and the protective conductor must be at least 1.0mm2. For equipment with a leakage current greater than 10mA, additional precautions are also required.

If you want to learn more about electrical testing, we regularly run PAT testing courses at venues across the country. Our experienced trainers will guide you through the process of conducting visual inspections, earth continuity tests, insulation resistance tests, leakage current tests and more. At the end of the course, you will have a thorough understanding of the principles of testing, as well as the skills and knowledge needed to perform these tests competently and confidently. Our courses are suitable for anyone who is responsible for the testing and maintenance of electrical equipment, including facilities managers, electricians, and health and safety professionals.