Making and Selling Lamps

We often receive enquiries about our PAT testing courses from people looking to start a small business making and selling small electrical items, typically lamps and other lighting products. There's a common misconception that all that is required is to carry out a PAT test. This article provides some information on the basic requirements for selling electrical equipment, specifically lighting products, in the UK.

Legal Requirements

If you are making and selling mains-powered electrical equipment, your product must comply with The Electrical Equipment (Safety) Regulations 2016. The regulations require you to carry out a conformity assessment and have technical documentation to demonstrate how your product has been designed and manufactured to meet the safety requirements. For a basic lamp design using standard components, this doesn't need to be over complicated. It will usually consist of drawings or photographs showing methods of construction, a wiring diagram, a parts list, supplier records and test results.

You must also create a Declaration of Conformity and add the UKCA mark to your product. The Declaration of Conformity is a mandatory document that is essentially a signed statement to declare that you take full responsibility for ensuring your product meets the safety requirements. It does not need to be supplied with the product, but you will need to have it available for market surveillance authorities on request. The UKCA mark is a visible indication that your product meets the safety requirements and must be applied to your product. We also have a separate article with information about the UKCA mark.

Product Standards

The recommended method to ensure your product meets the safety requirements is to follow a product standard. If your product meets the relevant product standard, it is automatically taken to be safe. The main product standard for lighting equipment is BS EN 60598. This is split into two parts. 60598-1 covers the general safety, construction, marking, wiring and testing requirements. The second part, 60598-2, is a series of accompanying standards specific to different types of lighting products, from street lights to emergency lighting. The most relevant to general domestic type lamps is 60598-2-4 Portable General Purpose Luminaires. Copies of product Standards can be purchased from the British Standards Institute (BSI) website. They are expensive, however, you can often access the online standards library for free by visiting your local library.

Complying With BS EN 60598

First a note on terminology. Technically the term 'lamp' is specific to the light-emitting part of a luminaire which we usually call a bulb. A luminaire is a complete electric light unit consisting of one or more lamps (bulbs). For simplicity, we will stick with the commonly used term lamp, when referring to the luminaire.

BS EN 60598 covers a whole series of mechanical, thermal, electrical and marking requirements. If your lamp is a basic design using standard electrical components, meeting the requirements shouldn't be a problem. However, the standard does contain specific requirements, so you must still carefully check that your design complies with the standard.

Mechanical Tests

The standard includes a number of mechanical tests. One of the most relevant is a stability test for table and floor standing lamps. There are also torque tests on screws and glands and a series of thermal tests.

Electrical Tests

The standard also requires that electrical conformity tests are carried out on all units during manufacture.

Electrical Testing

BS EN 60598 requires a functional test, an earth continuity test (for Class I construction) and either an electrical strength or an insulation resistance test.

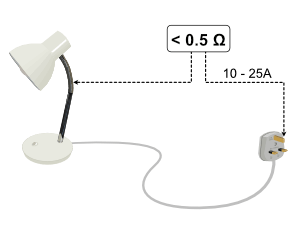

Earth Continuity Test

For Class I lamps an earth continuity test is required. This test measures the resistance of the protective conductor between the earth pin of the plug and the earthed metal parts of the lamp. This must be carried out with a minimum test current of 10A. However, most approval organisations, such as ASTA BEAB, recommend using a higher test current of 25A. The purpose of using a high current test, rather than a low current test using for example a multimeter, is to detect any weak points such as a single-strand connection.

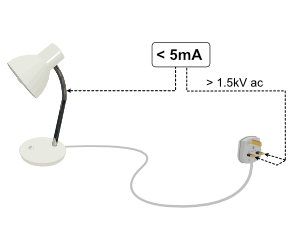

Electric Strength Test

The electric strength test (also called hipot, dielectric strength, or flash test), is used to determine the effectiveness of the insulation by applying a high voltage between the live conductors and the lamp body and measuring any current leaking across the insulation. This test is useful in detecting faults such as damaged or crushed insulation, loose wire strands and inadequate clearance distances. The minimum required test voltage is 1.5 kV ac. and the maximum allowable leakage is 5mA.

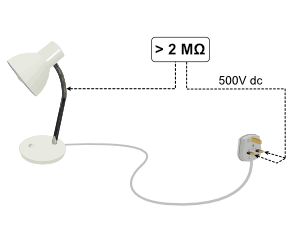

Insulation Resistance Test

As an alternative to the electric strength test, an insulation resistance test can be used. This measures the resistance of the insulation using a 500 Vdc test voltage. The resistance of the insulation must be greater than 2 MΩ. The insulation resistance test is a less vigorous test than the electric strength, so we recommend carrying out an electric strength test where possible.

Test Instruments

It is possible to use a PAT test instrument for production testing, however, most modern PAT testers are battery-powered and are not suitable because they do not have a high current earth continuity test. Additionally, the electric strength test is not routinely carried out during in-service testing, so only a few models can carry out this test. The PAT testers that we would recommend using for production testing are either the Metrel OmegaPat or Seaward Supernova. Both of these can carry out an earth continuity test at 25A and have the Electric Strength test (Flash Test). Test instruments specifically designed for production testing are also available. Seaward has a tester specifically designed for the production testing of luminaries.

Training Courses

Attending a PAT testing course is a good way to learn the basic test procedures that can then be applied to production testing, but it does not cover the legal requirements of electrical equipment manufacturing or compliance with product standards such as BS EN 60598.

Training courses specific to luminaire testing and compliance are available through the Lighting Industry Association (LIA). They also offer a range of membership services including a testing laboratory to independently verify the safety and performance of lighting products. www.thelia.org.uk

Weloveleds, an online supplier of LED lighting, runs a practical LED training course. The course covers the different types of LEDs available, how to use them, and how to wire them up to make sure they're safe. Weloveleds LED Training Course.

Tim Thornton Ceramics offers an online course titled "Making Electric Lamps". This course covers testing procedures as well as relevant standards and regulations. Making Electric Lamps Course

Additional Legislation

As well as The Electrical Equipment (Safety) Regulations, there is additional legislation that you must comply with.

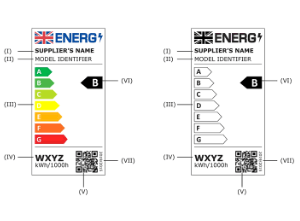

Ecodesign and Energy Information Regulations

The Ecodesign for Energy-Related Products and Energy Information (Lighting Products) Regulations require all lighting products sold in the UK have an energy performance label.

WEEE Directive

As a producer of electrical equipment, you must also meet the requirements of the waste electrical and electronic equipment regulations (WEEE). For most small manufacturers, the easiest way to do this is by joining the Distributor Takeback Scheme (DTS). You pay a fee that covers your WEEE obligations, with the money going towards supporting the recycling centres. You also need to mark your product with the crossed out wheeled bin symbol. The specification for the symbol is covered in the BS EN 50419 standard. There is also a requirement to keep a record of the amount of electrical equipment you produce and the records should be kept for at least 4 years.

Product liability Insurance

As a manufacturer, you take on the liability for your products under the Consumer Protection Act 1987. There is a possibility that you could be sued if one of your products causes damage to a third party; which could be property or another person. Product liability insurance is not a legal requirement but it does cover you against claims made against your business.

Component Suppliers

It may be tempting to source cheap imported components from sites like Alibaba or eBay, but the electrical products sold on these sites are often substandard or counterfeit and will compromise the safety of your product. We have an article highlighting dangerous counterfeit plugs sold on these sites.

We strongly advise sourcing components only from reputable suppliers that have quality assurance policies in place. Some examples include:

S.Lilley & Son, is the UK's leading manufacturer of lampholders and components for the Lighting Industry. All of the products in their range are tested at independent laboratories and certified to current BS EN ISO standards.

www.s-lilley.co.uk

Flexform Ltd is a UK cable manufacturing company focused on decorative flexible cables used within the lighting industry. Flexform are members of the LIA and have been certified in their quality assurance scheme.

flexform.co.uk

Upcycling and Refurbished Lamps

If you are refurbishing or restoring a lamp to sell, then this is classified as second-hand equipment, rather than a new electrical product. We have an article on selling second-hand electrical equipment.

If you are upcycling an item that was not previously a lamp, for example repurposing an old fire extinguisher into a lamp, this is effectively a new product and will therefore need to comply with The Electrical Equipment (Safety) Regulations.

Additional Resources

This website is provided for information purposes only and while every effort has been made to ensure that information is accurate and up-to-date, we cannot guarantee accuracy and we are not responsible for any errors or omissions. We therefore recommend that you carry out your own research and seek professional advice where necessary. Updated in November 2022 to reflect changes to the regulations.